HOW WE WORK

how

we work

see how we work

We tirelessly work to improve the flexibility of the design and the ability to understand the real needs of the customer based on his objectives.

For this reason, over the years our employees have become real consultants to support client companies that have complex projects to carry out requiring great flexibility.

We believe in the technical and technological innovation of our machinery in order to offer products designed by the best parametric modeling software and static and dynamic FEM analysis.

MACHINES

CREATED ON

CUSTOMER’S NEEDS

The company then builds lifting platforms and walkways to be applied to vertical lathes or large milling machines to bring the operator to height, self-propelled trolleys, tilters, pallet turners and other special machines for HANDLING, LIFTING AND TRANSPORT GOODS AND PEOPLE

see how we work

MACHINES CREATED ON CUSTOMER’S NEEDS

We tirelessly work to improve the flexibility of the design and the ability to understand the real needs of the customer based on his objectives.

For this reason, over the years our employees have become real consultants to support client companies that have complex projects to carry out requiring great flexibility.

We believe in the technical and technological innovation of our machinery in order to offer products designed by the best parametric modeling software and static and dynamic FEM analysis.

The company then builds lifting platforms and walkways to be applied to vertical lathes or large milling machines to bring the operator to height, self-propelled trolleys, tilters, pallet turners and other special machines for HANDLING, LIFTING AND TRANSPORT GOODS AND PEOPLE.

iso

9001

quality

& conformity

This allows us to have a very low rate of non-conformity / defects and be able to guarantee reliability and longevity of our products at the highest levels, even in critical conditions that require extreme performance.

quality & conformity

iso

9001

This allows us to have a very low rate of non-conformity / defects and be able to guarantee reliability and longevity of our products at the highest levels, even in critical conditions that require extreme performance.

This is the secret of the very low rate of non-compliance / defectiveness of our cylinders and our machines, products designed to ensure maximum reliability and extreme longevity even in work situations with extreme and repeated stress.

WE DESIGN AND BUILD:

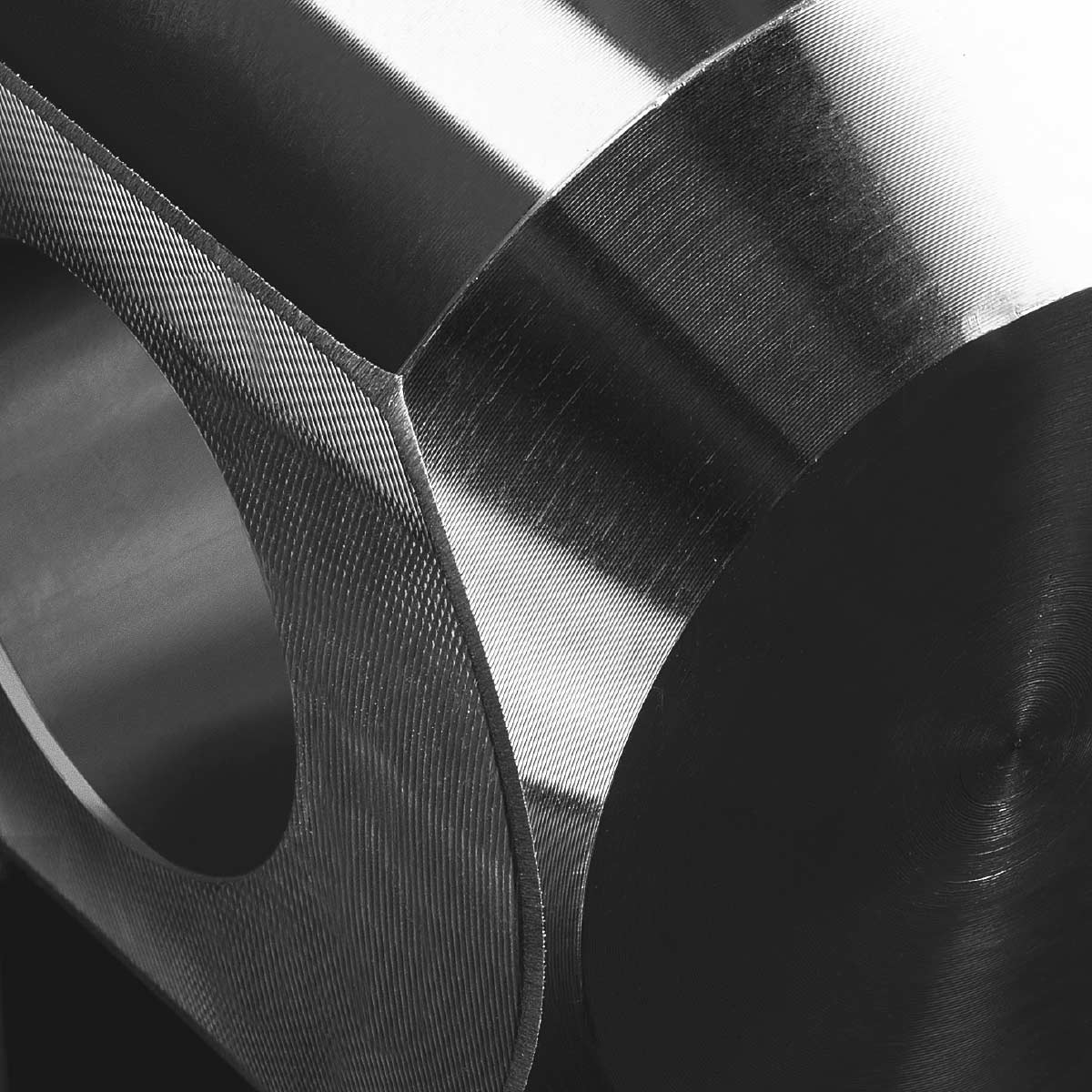

Hydraulic cylinders with bores greater than 50mm.

Systems for materials and people handling in the industrial sector, such as hydraulic and electric tilters and platforms, self-propelled trolleys and large capacity roller conveyors.

The investments we believe in are those that guarantee a more flexible design, a competitive production capacity and increasingly reliable and safe products.

PRECISION and PUNCTUALITY in the management of orders are the basis of the TRUST relationship that we develop with our customers, we work incessantly to update business processes in compliance with the most modern management techniques.

HOW

we work

The products are designed by the internal department, created with only Italian and European steel, tested on cutting-edge benches by carrying out multiple tests to ensure their technical specifications and certifications.

The company also uses only certified machinery and continuously trains its employees.

OMS Sordella guarantees complete traceability, through serial marking of each component and product. It also offers Certification of origin for all materials used, trial tests and VT (visual test), PT (penetrating liquids) and MT (magnetic) controls on all cylinders.

Thanks to this commitment towards its customers, the products meet the highest quality requirements demanded by the market and they are guaranteed by the following certifications:

/ ISO 9001:2015.

/ UNI EN ISO 15085-2: 2008 in accordance with class CL1 technical product standard which sets the guidelines to follow, for design and manufacture, in the welding of vehicles and railway components.

/ UNI EN ISO 15614-1:2019.

/ WPS e WPQR (welding procedures)

/ UNI EN ISO 5817:2014 (welding tests).

From the first contact, our technical staff helps you to shape even the most particular needs and to satisfy every type of requirement.

Furthermore, we are focused on PREVENTING the need for AFTER-SALES ASSISTANCE by making products with Italian and European steel only, testing them in our testing area and subjecting them to the most severe inspections.

how

we work

read more /

This is the secret of the very low rate of non-compliance / defectiveness of our cylinders and our machines, products designed to ensure maximum reliability and extreme longevity even in work situations with extreme and repeated stress.

WE DESIGN AND BUILD:

Hydraulic cylinders with bores greater than 50mm.

Systems for materials and people handling in the industrial sector, such as hydraulic and electric tilters and platforms, self-propelled trolleys and large capacity roller conveyors.

read more /

The products are designed by the internal department, created with only Italian and European steel, tested on cutting-edge benches by carrying out multiple tests to ensure their technical specifications and certifications.

The company also uses only certified machinery and continuously trains its employees.

OMS Sordella guarantees complete traceability, through serial marking of each component and product. It also offers Certification of origin for all materials used, trial tests and VT (visual test), PT (penetrating liquids) and MT (magnetic) controls on all cylinders.

Thanks to this commitment towards its customers, the products meet the highest quality requirements demanded by the market and they are guaranteed by the following certifications:

• ISO 9001: 2015.

• UNI EN ISO 15085-2: 2008 in accordance with class CL1 technical product standard which sets the guidelines to follow, for design and manufacture, in the welding of vehicles and railway components.

• UNI EN ISO 15614-1: 2019.

• WPS and WPQR (welding procedures)

• UNI EN ISO 5817: 2014 (welding tests).

read more /

The investments we believe in are those that guarantee a more flexible design, a competitive production capacity and increasingly reliable and safe products.

PRECISION and PUNCTUALITY in the management of orders are the basis of the TRUST relationship that we develop with our customers, we work incessantly to update business processes in compliance with the most modern management techniques.

read more /

From the first contact, our technical staff helps you to shape even the most particular needs and to satisfy every type of requirement.

Furthermore, we are focused on PREVENTING the need for AFTER-SALES ASSISTANCE by making products with Italian and European steel only, testing them in our testing area and subjecting them to the most severe inspections.

read more /

news &

extra

If you are intererested and desire further information fill the form here below.

Our technical staff will contact you soon

If you are intererested and desire further information fill the form here below.

Our technical staff will contact you soon